The Future of Pumps and Valves: How Technology is Revolutionizing the Industry

In a world where innovation and technology are constantly shaping industries, the pumps and valves sector is no exception. As we venture into the future, these essential components are undergoing a remarkable transformation, driven by cutting-edge advancements. From smart pumps that can self-monitor and diagnose issues to valves that seamlessly adjust to changing conditions, the future of pumps and valves is nothing short of revolutionary. This article explores the exciting developments that are reshaping the industry and the profound impact they will have on efficiency, cost-effectiveness, and sustainability. Join us as we delve into the world of digitalization, automation, and connectivity, and discover how these technological breakthroughs are revolutionizing the pumps and valves industry. Get ready to witness a new era of productivity and performance, where precision and reliability reign supreme.

The Impact of Technology on Pumps and Valves

Technology has always played a significant role in the evolution of the pumps and valves industry. However, recent advancements have taken this to a whole new level, transforming the way these components operate and perform. The integration of digital technologies, such as automation and connectivity, has paved the way for more efficient and intelligent systems. By leveraging the power of data and analytics, pumps and valves can now be optimized for maximum performance, reliability, and energy efficiency. These advancements are not only improving productivity but also reducing downtime and maintenance costs, making them a game-changer for industries that rely on pumps and valves.

Automation and Smart Technology in the Industry

One of the most significant advancements in the pumps and valves industry is the integration of automation and smart technology. Automation has revolutionized the way these components are controlled and monitored, enabling real-time adjustments and optimization. Smart pumps, equipped with sensors and actuators, can now self-monitor and diagnose issues, allowing for proactive maintenance and minimizing the risk of unexpected failures. Similarly, smart valves can dynamically adjust their position based on changing conditions, optimizing flow rates and reducing energy consumption. With automation and smart technology, the pumps and valves industry is witnessing a new era of efficiency, reliability, and operational intelligence.

IoT (Internet of Things) and Its Role in Pump and Valve Systems

The Internet of Things (IoT) has emerged as a key enabler of connectivity and data-driven decision-making in the pumps and valves industry. By connecting pumps and valves to a network of sensors and devices, IoT enables real-time monitoring, remote control, and predictive maintenance. For example, IoT-enabled pumps can transmit data about their operating conditions, including temperature, pressure, and flow rate, to a central control system. This data can then be analyzed to identify potential issues and trigger maintenance activities before failures occur. Similarly, IoT-enabled valves can provide valuable insights into the performance and condition of the system, allowing for proactive adjustments and optimization. The integration of IoT in pump and valve systems is unlocking new levels of efficiency, reliability, and cost-effectiveness.

Predictive Maintenance and Condition Monitoring

Traditionally, maintenance in the pumps and valves industry has been reactive, with components being repaired or replaced only after a failure occurs. However, with the advent of predictive maintenance and condition monitoring, this approach is rapidly changing. Predictive maintenance leverages data analytics and machine learning algorithms to anticipate failures and schedule maintenance activities accordingly. By continuously monitoring the performance and condition of pumps and valves, potential issues can be identified early on, allowing for timely intervention and minimizing the risk of unexpected downtime. Condition monitoring techniques, such as vibration analysis and thermal imaging, provide valuable insights into the health of the components, enabling proactive maintenance and extending their lifespan. With predictive maintenance and condition monitoring, the pumps and valves industry is shifting from a reactive to a proactive approach, resulting in improved reliability, reduced maintenance costs, and increased uptime.

Energy Efficiency and Sustainability in Pumps and Valves

Energy efficiency and sustainability have become critical considerations in the pumps and valves industry. With the rising cost of energy and increasing environmental concerns, there is a growing need for more efficient and eco-friendly solutions. Advancements in pump and valve technology are addressing these challenges head-on. For instance, variable speed drives (VSDs) are being widely adopted to optimize energy consumption by adjusting the speed of pumps and valves based on demand. This not only reduces energy wastage but also extends the lifespan of the components. Additionally, innovative valve designs, such as pressure-independent control valves (PICVs), are improving energy efficiency by maintaining a constant flow rate regardless of system pressure fluctuations. By prioritizing energy efficiency and sustainability, the pumps and valves industry is playing a crucial role in creating a more sustainable future.

Advancements in Pump and Valve Materials

The materials used in pumps and valves have a significant impact on their performance, durability, and maintenance requirements. Over the years, advancements in materials science have led to the development of new and improved materials that can withstand harsh operating conditions and corrosive environments. For instance, the use of advanced polymers and composite materials has improved the resistance of pumps and valves to chemical corrosion, reducing the need for frequent maintenance and replacement. Similarly, the use of ceramic materials in valve components has enhanced their wear resistance, resulting in longer lifespans and improved reliability. These advancements in pump and valve materials are enabling the industry to deliver more robust and reliable solutions, reducing downtime and maintenance costs.

The Role of Artificial Intelligence in Pump and Valve Operations

Artificial intelligence (AI) is transforming various industries, and the pumps and valves sector is no exception. AI algorithms can analyze vast amounts of data collected from sensors and devices, enabling intelligent decision-making and optimization. For example, AI-powered algorithms can analyze historical data to identify patterns and anomalies, allowing for predictive maintenance and early fault detection. AI can also optimize the operation of pumps and valves by continuously adjusting parameters based on real-time data and system requirements. By harnessing the power of AI, the pumps and valves industry can achieve unprecedented levels of efficiency, reliability, and performance.

Challenges and Opportunities in Adopting New Technologies

While the future of pumps and valves seems promising, there are challenges that need to be addressed to fully leverage the potential of new technologies. One of the key challenges is the integration of legacy systems with modern technology. Many existing pumps and valves installations were not designed with automation and connectivity in mind, making it challenging to retrofit them with smart technology. Additionally, there is a need for skilled professionals who can understand and operate the new technologies effectively. Training and upskilling the workforce is essential to ensure the successful adoption and implementation of these advancements. Despite these challenges, the opportunities presented by new technologies in the pumps and valves industry are immense. By embracing digitalization, automation, and connectivity, companies can gain a competitive edge, improve efficiency, reduce costs, and deliver better products and services to their customers.

Conclusion: The Future of Pumps and Valves in the Industry

The future of the pumps and valves industry is undoubtedly exciting. With advancements in automation, smart technology, IoT, predictive maintenance, energy efficiency, materials, and artificial intelligence, these essential components are undergoing a profound transformation. The integration of these technologies is revolutionizing the way pumps and valves operate, perform, and are maintained. Efficiency, reliability, and sustainability are at the forefront, enabling industries to achieve new levels of productivity and performance. As the pumps and valves industry continues to embrace the digital revolution, we can expect to witness a new era of innovation, where precision and reliability reign supreme. The future of pumps and valves is here, and it promises to reshape industries and drive us towards a more efficient and sustainable future.

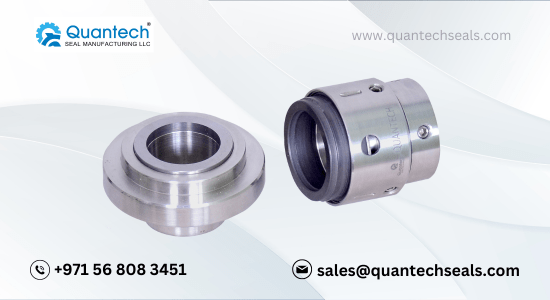

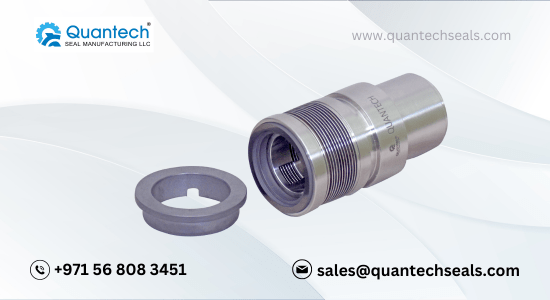

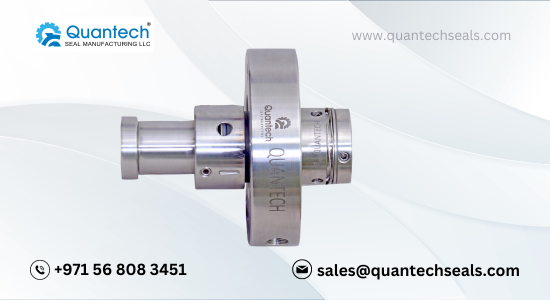

Mechanical Seal Manufacturer and Supplier in UAE.

Quantech Seal Manufacturing LLC is a mechanical seal manufacturer and supplier in Dubai, UAE. We produce a wide range of mechanical seal products for various industries such as papermaking, chemical engineering, oil refining, machinery manufacturing, pharmaceuticals, food processing, etc.,. Our products include Single Coil Seals, Multi Spring Seals, Conical Spring Seals, Reverse Balanced Seals, Rubber Bellow Seals, Single Acting Seals, Teflon Bellow Seals, Metal Bellow Seals, Wave Spring Seals, Single Cartridge Seals, Double Cartridge Seals, Dry Seals, Reactor Seals, Agitator Seals etc.,. We export our products to various countries such as Saudi Arabia, Egypt, Pakistan, West Africa, Nigeria, Oman, India, Singapore, China, Sri Lanka, Qatar, Ukrain, etc.

Single Coil Seal

Multi Coil Seal

Bellow Type Mechanical Seal

Wave Spring Mechanical Seal

Cartridges Mechanical Seal

Reactor Mechanical Seal

Mechanical Seal Manufacturer in Dubai, UAE.

If you are looking for Mechanical Seal Manufacturer in Dubai, United Arab Emirates. Quantech Seal LLC is the right choice for you. We measure your specific performance requirements and budget you need. For a detailed price quote, please call +971503915144 or email sales@quantechseals.com. Our team experts will help you with the latest products and standards ensures the best possible Mechanical Seal for your applications.