Are you tired of dealing with mechanical seal issues that seem to keep recurring? Frustrating and time-consuming, these problems can disrupt your operations and eat into your profits. But fear not, because help is at hand. In this article, we will delve into the world of mechanical seals and provide you with expert tips and solutions to troubleshoot the most common issues. Whether you are dealing with leakage, excessive heat, or seal failure, our comprehensive guide will equip you with the knowledge and strategies to overcome these challenges. Quantech Seal Manufacturer LLC, Dubai, with years of experience in the industry, we understand the importance of maintaining smooth and efficient operations. That's why we have compiled this guide to help you identify the root causes of mechanical seal issues and implement effective solutions. Get ready to bid adieu to those recurring headaches and enjoy a trouble-free operation with our expert advice.

Importance of Proper Maintenance for Mechanical Seals

Mechanical seals play a crucial role in preventing leaks and ensuring the smooth operation of pumps and other equipment. However, like any other component, they require regular maintenance to perform optimally. Proper maintenance not only extends the lifespan of your mechanical seals but also minimizes the risk of costly breakdowns. Routine inspection, cleaning, and lubrication are essential for keeping seals in top condition. In addition, following the manufacturer's recommended maintenance schedule and using high-quality replacement parts can greatly reduce the likelihood of seal issues. By investing time and effort into maintaining your mechanical seals, you can save yourself from the headaches and expenses associated with frequent breakdowns.

Common Mechanical Seal Issues

Mechanical seals are subjected to a wide range of operating conditions, which can lead to various problems. Understanding the common issues that can arise will help you identify and address them effectively. The most prevalent mechanical seal problems include:

1. Leakage: One of the most frustrating issues faced by operators is seal leakage. This can occur due to factors such as worn or damaged seals, improper installation, excessive vibration, or misalignment. Leakage not only wastes valuable resources but can also cause environmental concerns and safety hazards.

2. Excessive Heat: Overheating can lead to seal failure and reduced equipment performance. Common causes of excessive heat include inadequate cooling systems, high operating temperatures, friction, or improper lubrication. It is crucial to monitor temperature levels and address any overheating issues promptly.

3. Seal Failure: Mechanical seal failure can result from a combination of factors, including wear and tear, poor installation, excessive pressure, corrosion, or misalignment. A failed seal can cause severe equipment damage and downtime, resulting in significant financial losses.

Identifying and Diagnosing Mechanical Seal Problems

When facing mechanical seal issues, it is essential to accurately identify and diagnose the root cause. This allows you to implement targeted solutions and prevent recurring problems. Here are some steps to help you identify the source of the issue:

1. Visual Inspection: Start by visually inspecting the seals for any signs of leakage, wear, or damage. Look for cracks, discoloration, or irregularities in the seal faces, gaskets, or O-rings. Take note of any abnormal vibrations, noises, or temperature fluctuations.

2. Review Operating Conditions: Evaluate the operating conditions under which the seals are exposed. Consider factors such as pressure, temperature, speed, and fluid compatibility. Check if the seals are designed to handle the specific conditions they are subjected to.

3. Conduct Tests: Perform tests such as pressure tests, leak tests, or performance tests to gather more data about the seal's behavior. This can help pinpoint the exact cause of the problem and guide you in finding the appropriate solution.

Once you have identified the problem, it's time to move on to troubleshooting and finding effective solutions.

Expert Tips for Troubleshooting Mechanical Seal Issues

Troubleshooting mechanical seal issues requires a systematic approach and a deep understanding of the underlying problems. Here are some expert tips to help you troubleshoot common mechanical seal issues:

1. Address Misalignment: Misalignment can put excessive stress on seals, leading to premature failure. Ensure that the equipment is properly aligned and consider using alignment tools or consulting with a professional if needed.

2. Optimize Lubrication: Proper lubrication is essential for reducing friction and heat generation. Use the recommended lubricants and ensure that the seals are adequately lubricated at all times. Regularly check the lubrication systems and replace or refill as necessary.

3. Maintain Cleanliness: Contaminants such as dirt, debris, or corrosive substances can damage seals and cause leaks. Implement proper filtration and cleaning systems to remove contaminants from the operating environment. Regularly clean the seals and associated components to prevent build-up.

4. Monitor Operating Conditions: Keep a close eye on the operating conditions, including temperature, pressure, and speed. Ensure that the equipment is operating within the recommended limits and make adjustments if necessary. Consider installing monitoring systems to provide real-time data on the seal's performance.

Solutions for Common Mechanical Seal Problems

Now that we have identified the common mechanical seal issues and discussed troubleshooting tips, let's explore some effective solutions for specific problems:

1. Leakage: To address leakage, start by checking the seal faces for wear or damage. If necessary, replace the seals with high-quality, compatible alternatives. Additionally, ensure proper installation and alignment, and consider using sealing products or coatings to enhance the seal's performance.

2. Excessive Heat: To combat excessive heat, improve cooling systems by adding heat exchangers or increasing flow rates. Consider using heat-resistant seals and lubricants designed for high-temperature applications. Properly insulate equipment and optimize ventilation to dissipate heat effectively.

3. Seal Failure: When dealing with seal failure, evaluate the root cause and take corrective measures. This may involve replacing worn or damaged seals, addressing misalignment or excessive pressure, or improving lubrication systems. Consult with experts if needed to identify the best course of action.

Proper Installation and Maintenance Techniques for Preventing Future Issues

Preventing mechanical seal issues starts with proper installation and maintenance techniques. Here are some best practices to follow:

1. Follow Manufacturer's Guidelines: Always adhere to the manufacturer's guidelines for seal installation, including torque specifications, alignment procedures, and recommended lubrication. Deviating from these instructions can lead to premature failure.

2. Train Personnel: Ensure that your maintenance personnel are properly trained in seal installation, maintenance, and troubleshooting. This will empower them to identify potential issues early on and take appropriate action.

3. Implement Preventive Maintenance: Regularly inspect and clean seals, replace worn or damaged components, and perform routine maintenance tasks. This proactive approach can help identify minor issues before they escalate into major problems.

4. Keep Records: Maintain detailed records of seal installations, maintenance activities, and any issues encountered. This information can provide valuable insights for future troubleshooting and decision-making.

Importance of Choosing the Right Mechanical Seal for Your Application

Selecting the appropriate mechanical seal for your specific application is crucial for long-term performance and reliability. Factors to consider when choosing a seal include:

1. Operating Conditions: Evaluate the temperature, pressure, speed, and fluid compatibility requirements of your application. Choose a seal that can withstand these conditions without compromising performance.

2. Material Compatibility: Select seals made from materials that are compatible with the fluids and chemicals used in your process. Consider factors such as corrosion resistance, abrasion resistance, and chemical compatibility.

3. Seal Type: Different seal types, such as single seals, double seals, or cartridge seals, offer varying levels of performance and protection. Choose a seal type that aligns with your specific needs and operating conditions.

4. Expert Advice: Consult with mechanical seal experts or manufacturers to ensure you choose the best seal for your application. They can provide valuable insights and recommendations based on their experience and industry knowledge.

Hiring Professional Assistance for Complex Mechanical Seal Problems

While many mechanical seal issues can be resolved through proper maintenance and troubleshooting techniques, some problems may require professional assistance. Complex issues such as extensive seal damage, equipment malfunctions, or recurring problems may necessitate the expertise of experienced professionals. Engaging with specialized mechanical seal service providers or consultants can help you diagnose and resolve these challenges effectively, minimizing downtime and maximizing equipment performance.

Conclusion and Final Thoughts

Mechanical seal issues can be a major headache for operators, causing disruptions, leaks, and equipment failures. However, by following proper maintenance practices, troubleshooting techniques, and implementing effective solutions, you can overcome these challenges and enjoy trouble-free operations. Remember to prioritize regular maintenance, accurately diagnose problems, and address them promptly. By choosing the right mechanical seal for your application and seeking professional assistance when needed, you can ensure the longevity and reliability of your equipment. So bid adieu to those recurring headaches, and say hello to smooth and efficient operations with our expert tips and solutions.

Now that you are armed with comprehensive knowledge and expert advice on troubleshooting common mechanical seal issues, it's time to put that knowledge into action. Implement the tips and techniques outlined in this guide, and watch as your mechanical seal problems become a thing of the past. Smooth operations, increased productivity, and reduced downtime await you. Take control of your mechanical seals and enjoy the benefits of a trouble-free operation.

Mechanical Seal Manufacturer and Supplier in UAE.

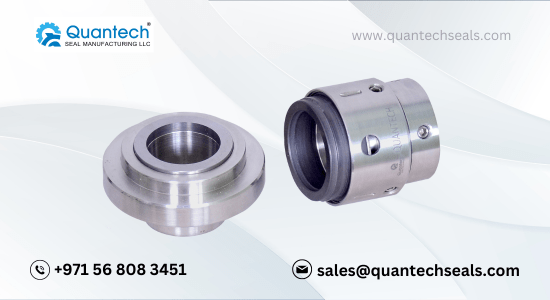

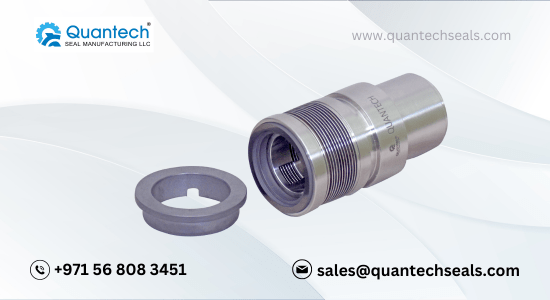

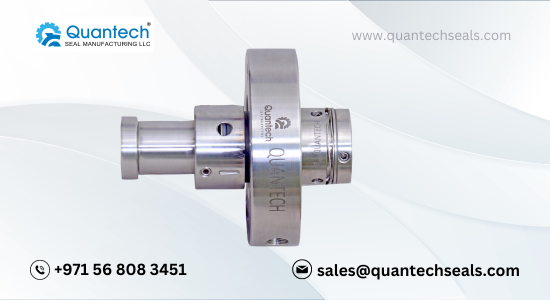

Quantech Seal Manufacturing LLC is a mechanical seal manufacturer and supplier in Dubai, UAE. We produce a wide range of mechanical seal products for various industries such as papermaking, chemical engineering, oil refining, machinery manufacturing, pharmaceuticals, food processing, etc.,. Our products include Single Coil Seals, Multi Spring Seals, Conical Spring Seals, Reverse Balanced Seals, Rubber Bellow Seals, Single Acting Seals, Teflon Bellow Seals, Metal Bellow Seals, Wave Spring Seals, Single Cartridge Seals, Double Cartridge Seals, Dry Seals, Reactor Seals, Agitator Seals etc.,. We export our products to various countries such as Saudi Arabia, Egypt, Pakistan, West Africa, Nigeria, Oman, India, Singapore, China, Sri Lanka, Qatar, Ukrain, etc.

Single Coil Seal

Multi Coil Seal

Bellow Type Mechanical Seal

Wave Spring Mechanical Seal

Cartridges Mechanical Seal

Reactor Mechanical Seal

Mechanical Seal Manufacturer in Dubai, UAE.

If you are looking for Mechanical Seal Manufacturer in Dubai, United Arab Emirates. Quantech Seal LLC is the right choice for you. We measure your specific performance requirements and budget you need. For a detailed price quote, please call +971503915144 or email sales@quantechseals.com. Our team experts will help you with the latest products and standards ensures the best possible Mechanical Seal for your applications.